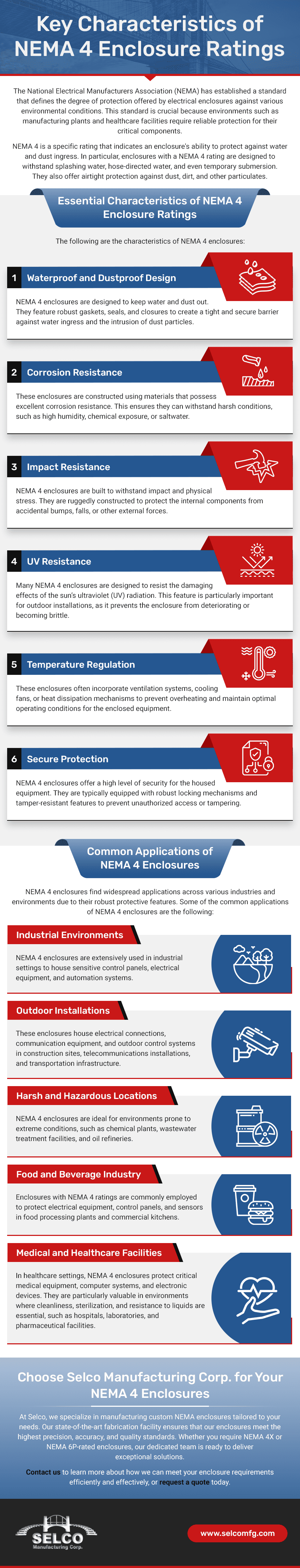

The National Electrical Manufacturers Association (NEMA) has established a standard that defines the degree of protection offered by electrical enclosures against various environmental conditions. This standard is crucial because environments such as manufacturing plants and healthcare facilities require reliable protection for their critical components.

NEMA 4 is a specific rating that indicates an enclosure’s ability to protect against water and dust ingress. In particular, enclosures with a NEMA 4 rating are designed to withstand splashing water, hose-directed water, and even temporary submersion. They also offer airtight protection against dust, dirt, and other particulates.

This article will delve into the characteristics and common applications of NEMA 4 enclosures, helping you understand their significance in various industries.

Essential Characteristics of NEMA 4 Enclosure Ratings

The following are the characteristics of NEMA 4 enclosures:

Waterproof and Dustproof Design

NEMA 4 enclosures are designed to keep water and dust out. They feature robust gaskets, seals, and closures to create a tight and secure barrier against water ingress and the intrusion of dust particles.

Corrosion Resistance

These enclosures are constructed using materials that possess excellent corrosion resistance. This ensures they can withstand harsh conditions, such as high humidity, chemical exposure, or saltwater.

Impact Resistance

NEMA 4 enclosures are built to withstand impact and physical stress. They are ruggedly constructed to protect the internal components from accidental bumps, falls, or other external forces.

UV Resistance

Many NEMA 4 enclosures are designed to resist the damaging effects of the sun’s ultraviolet (UV) radiation. This feature is particularly important for outdoor installations, as it prevents the enclosure from deteriorating or becoming brittle.

Temperature Regulation

These enclosures often incorporate ventilation systems, cooling fans, or heat dissipation mechanisms to prevent overheating and maintain optimal operating conditions for the enclosed equipment.

Secure Protection

NEMA 4 enclosures offer a high level of security for the housed equipment. They are typically equipped with robust locking mechanisms and tamper-resistant features to prevent unauthorized access or tampering.

Common Applications of NEMA 4 Enclosures

NEMA 4 enclosures find widespread applications across various industries and environments due to their robust protective features. Some of the common applications of NEMA 4 enclosures are the following:

Industrial Environments

NEMA 4 enclosures are extensively used in industrial settings to house sensitive control panels, electrical equipment, and automation systems.

Outdoor Installations

These enclosures house electrical connections, communication equipment, and outdoor control systems in construction sites, telecommunications installations, and transportation infrastructure.

Harsh and Hazardous Locations

NEMA 4 enclosures are ideal for environments prone to extreme conditions, such as chemical plants, wastewater treatment facilities, and oil refineries.

Food and Beverage Industry

Enclosures with NEMA 4 ratings are commonly employed to protect electrical equipment, control panels, and sensors in food processing plants and commercial kitchens.

Medical and Healthcare Facilities

In healthcare settings, NEMA 4 enclosures protect critical medical equipment, computer systems, and electronic devices. They are particularly valuable in environments where cleanliness, sterilization, and resistance to liquids are essential, such as hospitals, laboratories, and pharmaceutical facilities.

Choose Selco Manufacturing Corp. for Your NEMA 4 Enclosures

At Selco, we specialize in manufacturing custom NEMA enclosures tailored to your needs. Our state-of-the-art fabrication facility ensures that our enclosures meet the highest precision, accuracy, and quality standards. Whether you require NEMA 4X or NEMA 6P-rated enclosures, our dedicated team is ready to deliver exceptional solutions.

Contact us to learn more about how we can meet your enclosure requirements efficiently and effectively, or request a quote today.