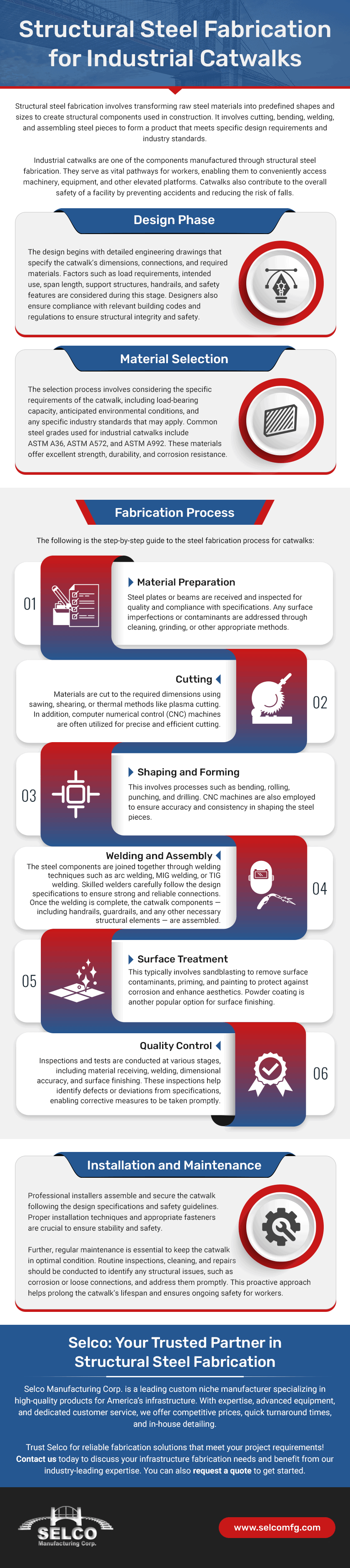

Structural steel fabrication involves transforming raw steel materials into predefined shapes and sizes to create structural components used in construction. It involves cutting, bending, welding, and assembling steel pieces to form a product that meets specific design requirements and industry standards.

Industrial catwalks are one of the components manufactured through structural steel fabrication. They serve as vital pathways for workers, enabling them to conveniently access machinery, equipment, and other elevated platforms. Catwalks also contribute to the overall safety of a facility by preventing accidents and reducing the risk of falls.

This article will delve into the structural steel fabrication process for industrial catwalks, covering the key steps involved from design to installation.

Design Phase

The design begins with detailed engineering drawings that specify the catwalk’s dimensions, connections, and required materials. Factors such as load requirements, intended use, span length, support structures, handrails, and safety features are considered during this stage. Designers also ensure compliance with relevant building codes and regulations to ensure structural integrity and safety.

Material Selection

The selection process involves considering the specific requirements of the catwalk, including load-bearing capacity, anticipated environmental conditions, and any specific industry standards that may apply. Common steel grades used for industrial catwalks include ASTM A36, ASTM A572, and ASTM A992. These materials offer excellent strength, durability, and corrosion resistance.

Fabrication Process

The following is the step-by-step guide to the steel fabrication process for catwalks:

Step 1: Material Preparation

Steel plates or beams are received and inspected for quality and compliance with specifications. Any surface imperfections or contaminants are addressed through cleaning, grinding, or other appropriate methods.

Step 2: Cutting

Materials are cut to the required dimensions using sawing, shearing, or thermal methods like plasma cutting. In addition, computer numerical control (CNC) machines are often utilized for precise and efficient cutting.

Step 3: Shaping and Forming

This involves processes such as bending, rolling, punching, and drilling. CNC machines are also employed to ensure accuracy and consistency in shaping the steel pieces.

Step 4: Welding and Assembly

The steel components are joined together through welding techniques such as arc welding, MIG welding, or TIG welding. Skilled welders carefully follow the design specifications to ensure strong and reliable connections. Once the welding is complete, the catwalk components — including handrails, guardrails, and any other necessary structural elements — are assembled.

Step 5: Surface Treatment

This typically involves sandblasting to remove surface contaminants, priming, and painting to protect against corrosion and enhance aesthetics. Powder coating is another popular option for surface finishing.

Step 6: Quality Control

Inspections and tests are conducted at various stages, including material receiving, welding, dimensional accuracy, and surface finishing. These inspections help identify defects or deviations from specifications, enabling corrective measures to be taken promptly.

Installation and Maintenance

Professional installers assemble and secure the catwalk following the design specifications and safety guidelines. Proper installation techniques and appropriate fasteners are crucial to ensure stability and safety.

Further, regular maintenance is essential to keep the catwalk in optimal condition. Routine inspections, cleaning, and repairs should be conducted to identify any structural issues, such as corrosion or loose connections, and address them promptly. This proactive approach helps prolong the catwalk’s lifespan and ensures ongoing safety for workers.

Selco: Your Trusted Partner in Structural Steel Fabrication

Selco Manufacturing Corp. is a leading custom niche manufacturer specializing in high-quality products for America’s infrastructure. With expertise, advanced equipment, and dedicated customer service, we offer competitive prices, quick turnaround times, and in-house detailing.

Trust Selco for reliable fabrication solutions that meet your project requirements! Contact us today to discuss your infrastructure fabrication needs and benefit from our industry-leading expertise. You can also request a quote to get started.